News Story

PHARENHEITS Program Could Yield Cooler Chip Stacks

Michael Ohadi, Minta Martin Professor, University of Maryland.

Researchers from the University of Maryland (UMD) are part of a newly-announced project led by HRL Laboratories that aims to develop an effective cooling system for stacks of microelectronic chips that perform functions ranging from processing to memory.

As part of the program, dubbed PHased ARray with INnovative HEterogeneously Integrated Thermal Solution (PHARINHEITS), Minta Martin Professor Michael Ohadi of the Department of Mechanical Engineering will lead a UMD team focused on improved heat flow in microchannels, which are embedded into a semiconductor and allow for more efficient routing of heat out of the electronics. In doing so, they aim to alleviate the intense heat density that has proved to be an important downside of so-called Heterogeneous Integration (HI) chip stacks.

Such configurations, in which multiple semiconductors with different functionalities are arranged on top of each other, are being used for AI and other applications that demand high power combined with smaller footprints. While offering many advantages, such stacks have proved notoriously difficult to cool, mainly because of the heat density and the sophisticated packaging involved.

“We need to cool the heat equivalent of more than 190 laptop CPUs, but in the size of a single CPU package,” said Christopher Roper, Principal Investigator at HRL Laboratories, in a recent press release.

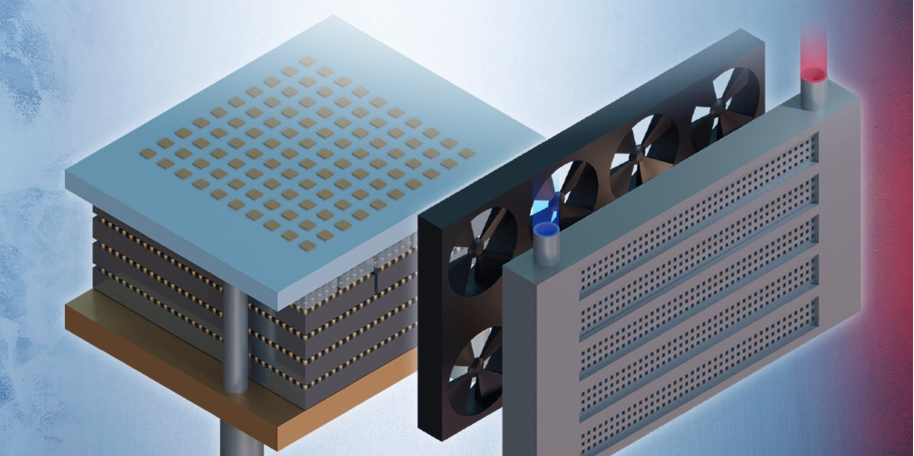

HRL Laboratories plans to develop a superior cooling system for stacks of microelectronic chips and surpass heat transfer metrics set out by the Defense Advanced Research Projects Agency (DARPA). The program aims to create compact thermal management technology in a chip stack using 3D Heterogeneous Integration (3DHI). [Photo credit: HRL Laboratories]

To help solve this problem, Ohadi plans to implement a patented method developed in his lab, in which the fluid and heat flow fields are managed in such a way that the flow runs short distances before changing its direction, thus enhancing the heat transfer coefficients while reducing the pressure drops. The resulting perturbations lead to what he terms ‘enhanced mixing,’ which in turn speeds up heat transfer rates.

Ohadi and his team will also be utilizing their substantial expertise in additively manufactured—specifically, through 3D printing—heat exchangers and thermal management systems to produce coolers that are smaller in size but deliver high heat removal rates. “The design complexity and feature dimensions of the components are such that manufacturing them with conventional manufacturing methods is very difficult, if not impossible,” he said. “You can’t really accomplish this with regular manufacturing techniques.”

Ohadi joined the UMD mechanical engineering faculty in 1990. He is a founding member of the Center for Environmental Energy Engineering.

In being selected for the program, he and his team are collaborating with distinguished experts at HRL laboratories (the prime contractor), Stanford University, the Lincoln Labs at the Massachusetts Institute of Technology, and Purdue University. Together, the participating research teams have set their sights on developing the next-generation 3D-printed HI electronics that surpass earlier versions through smart and sophisticated packaging design and integration, supported by innovative high-efficiency thermal management.

That, in turn, will help foster growth in systems capabilities, particularly in radio frequency systems, image analysis, and high-performance computing, including artificial intelligence and machine learning, HRL Laboratories said.

Published February 12, 2025